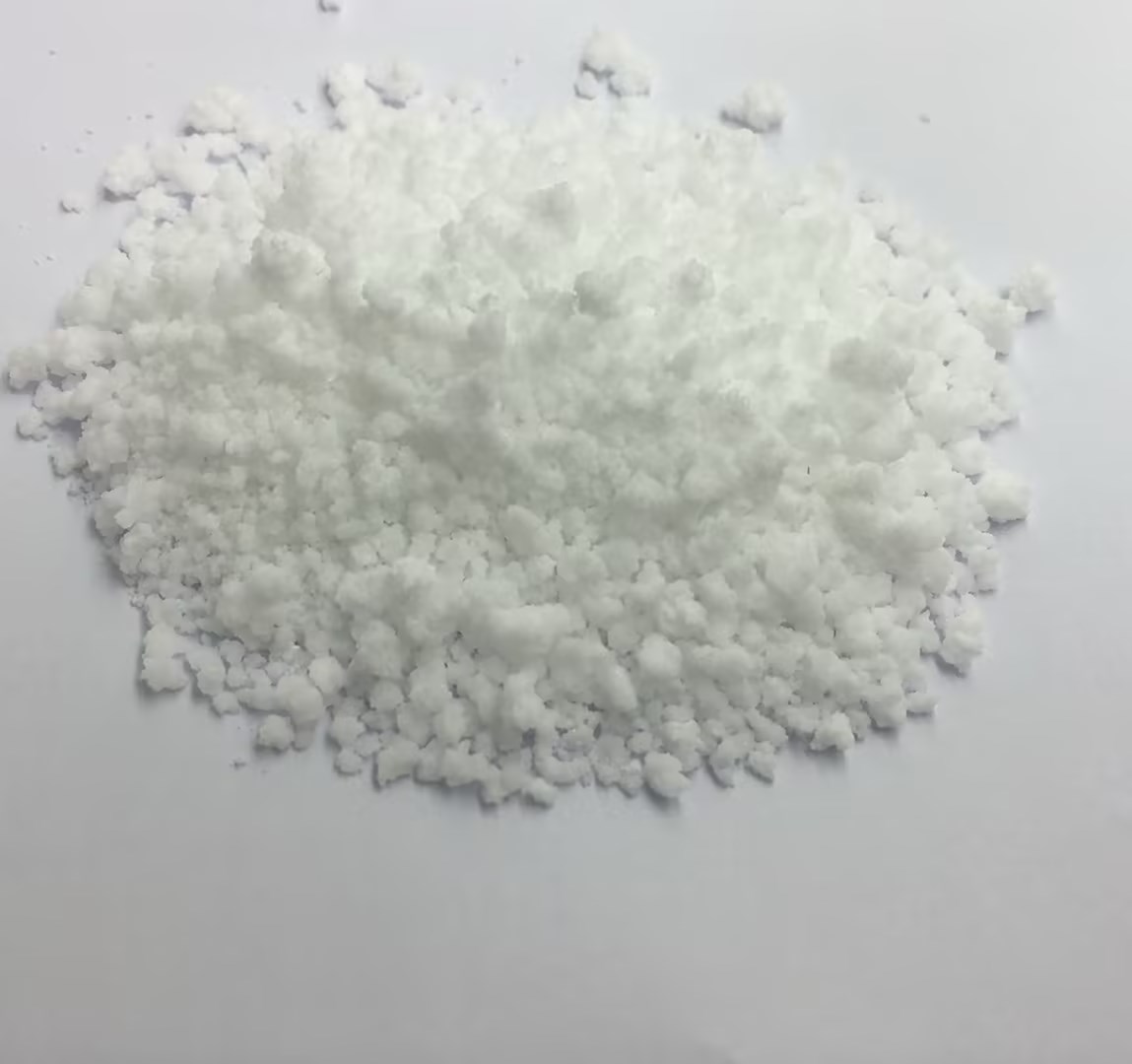

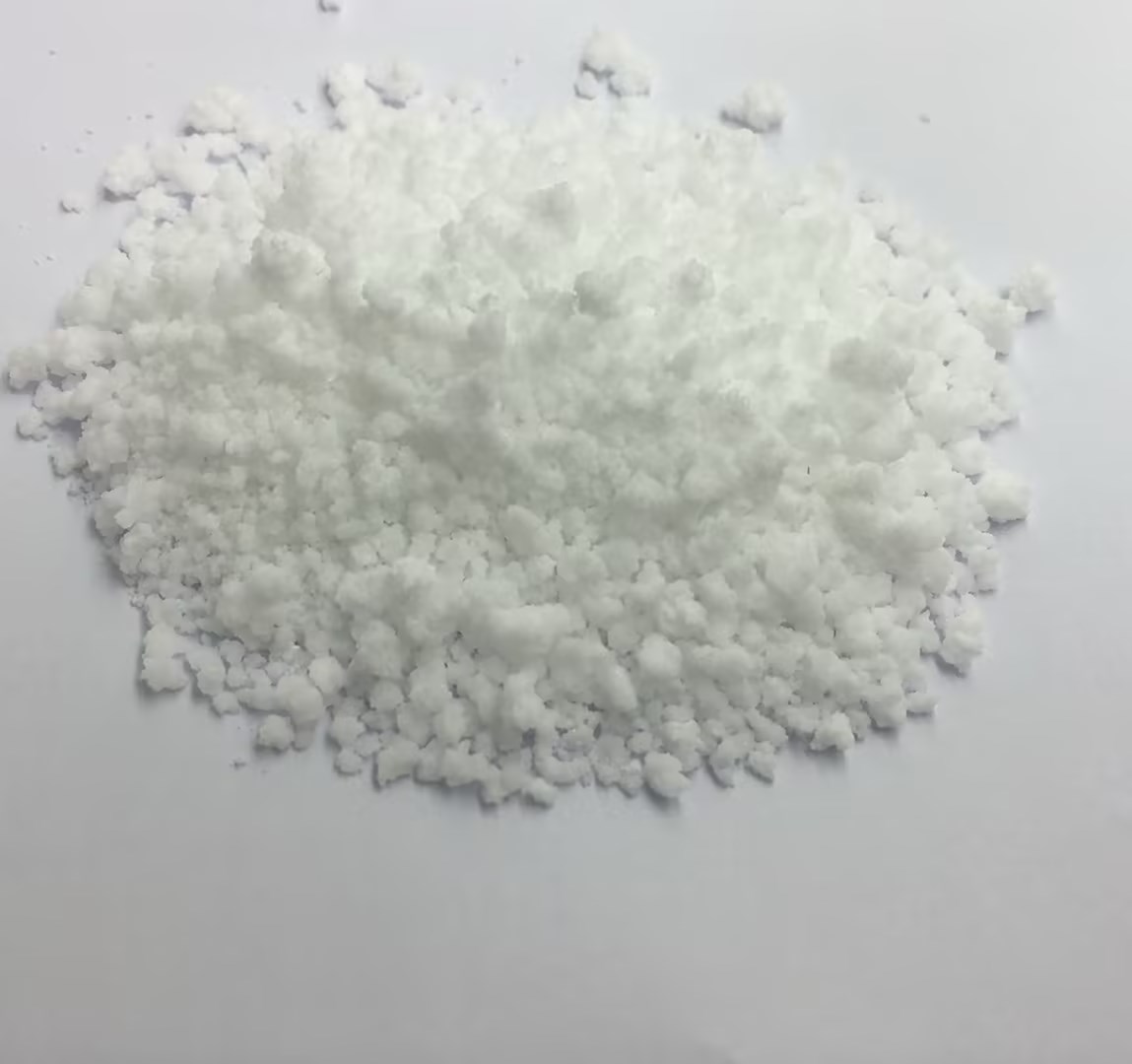

Gas phase white carbon black, as a type of high-end silicon material, plays a crucial role in the rubber industry due to its unique hydrophilic properties. This white carbon black is synthesized by gas-phase method, which has high dispersibility and fine particle structure, making it an ideal choice for enhancing the mechanical properties of rubber.

https://www.iotasilica.com/productcategory-precipitated.html

The surface of hydrophilic gas-phase white carbon black is rich in hydroxyl groups, which are easily combined with polar groups in rubber to form strong chemical bonds. This bonding not only improves the tensile strength and tear strength of rubber, but also significantly enhances the wear resistance and aging resistance of rubber. In tire manufacturing, the addition of hydrophilic aqueous phase white carbon black significantly improves the driving safety of tires, reduces rolling resistance, and extends the service life of tires. In addition, it can effectively improve the wet grip performance of rubber, ensuring the stability and handling of vehicles on rainy or slippery roads.

With the increasingly strict environmental regulations, the rubber industry is facing pressure for green transformation. Gas phase white carbon black is gradually becoming a key material for the green transformation of the rubber industry due to its low volatile organic compound (VOCs) emissions and low-energy production process. By optimizing the synthesis process and surface treatment technology, the hydrophilic properties of gas-phase white carbon black have been further improved, providing strong support for the high-quality development of the rubber industry.