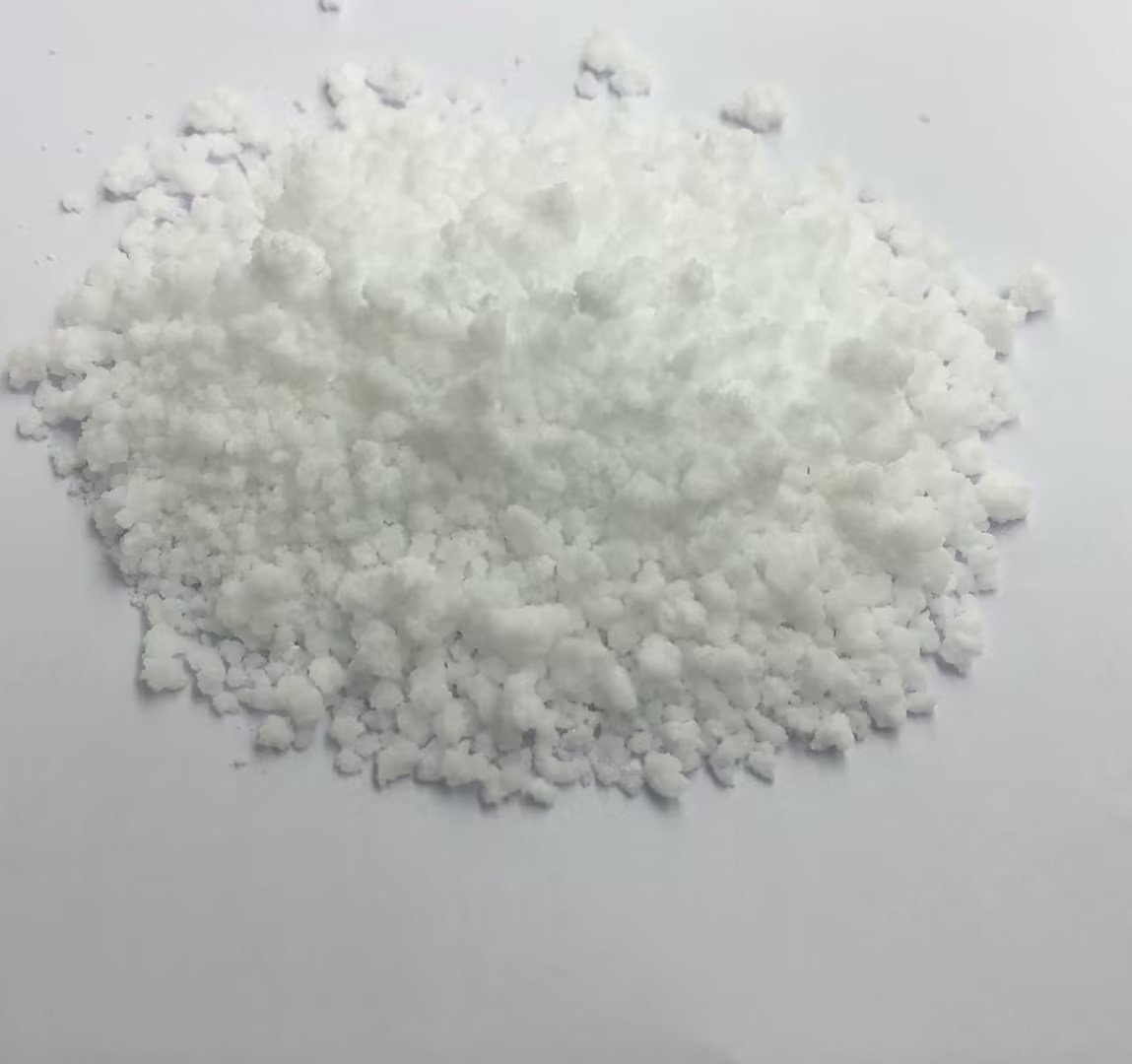

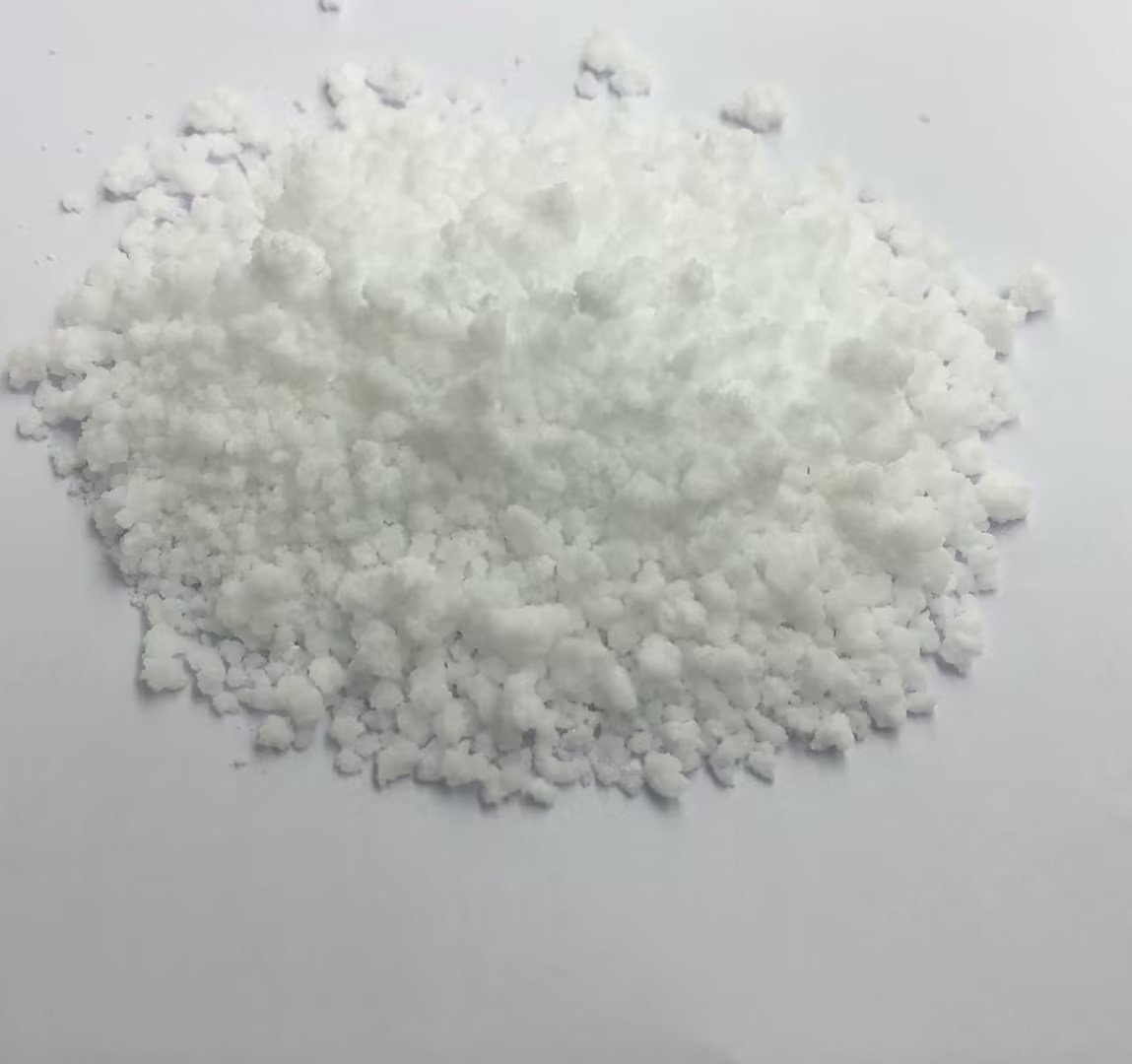

Gas phase hydrophobic white carbon black is endowed with excellent hydrophobic properties through a special surface treatment process. This unique performance demonstrates extraordinary potential in the field of plastic modification.

https://www.iotasilica.com/productcategory-precipitated.html

Adding hydrophobic gas-phase white carbon black to common plastics such as polyethylene (PE) and polypropylene (PP) can significantly improve the impact strength, rigidity, and heat resistance of the material. Meanwhile, the hydrophobic properties make white carbon black particles more stable in plastic melts, reducing agglomeration and promoting uniform dispersion of the material. This helps to improve the dimensional stability and surface glossiness of the product, making plastic products more beautiful and durable.

In addition, hydrophobic white carbon black can effectively enhance the weather resistance and aging resistance of plastics. In outdoor application environments, plastic products are often eroded by natural factors such as sunlight, wind and rain. The addition of hydrophobic white carbon black can protect plastic products from damage caused by these factors and extend their service life.

The application of gas-phase hydrophobic white carbon black is becoming an important force in promoting the upgrading of the plastic industry in the production of high-performance plastic products such as automotive interior parts, electronic and electrical casings, and building pipelines. By continuously optimizing the formula and process conditions, gas-phase hydrophobic white carbon black will bring more innovation and breakthroughs to the plastics industry.

Innovative Application of Gas phase Hydrophobic White Carbon Black in Plastic Modification

Gas phase hydrophobic white carbon black is endowed with excellent hydrophobic properties through a special surface treatment process. This unique performance demonstrates extraordinary potential in the field of plastic modification.

Adding hydrophobic gas-phase white carbon black to common plastics such as polyethylene (PE) and polypropylene (PP) can significantly improve the impact strength, rigidity, and heat resistance of the material. Meanwhile, the hydrophobic properties make white carbon black particles more stable in plastic melts, reducing agglomeration and promoting uniform dispersion of the material. This helps to improve the dimensional stability and surface glossiness of the product, making plastic products more beautiful and durable.

In addition, hydrophobic white carbon black can effectively enhance the weather resistance and aging resistance of plastics. In outdoor application environments, plastic products are often eroded by natural factors such as sunlight, wind and rain. The addition of hydrophobic white carbon black can protect plastic products from damage caused by these factors and extend their service life.

The application of gas-phase hydrophobic white carbon black is becoming an important force in promoting the upgrading of the plastic industry in the production of high-performance plastic products such as automotive interior parts, electronic and electrical casings, and building pipelines. By continuously optimizing the formula and process conditions, gas-phase hydrophobic white carbon black will bring more innovation and breakthroughs to the plastics industry.