Gas phase white carbon black: a treasure of high-tech ultrafine inorganic new materials

product link: https://www.iotasilica.com/product-fumed-silica-iota-hl4300.html

Gas phase white carbon black, as an extremely important high-tech ultrafine inorganic new material, is playing an irreplaceable role in materials science and industry with its unique properties and wide application fields. This article will delve into the basic characteristics, production processes, application areas, and market prospects of gas-phase white carbon black, in order to provide readers with a comprehensive and in-depth understanding.

1、 Basic characteristics

1、 Basic characteristics

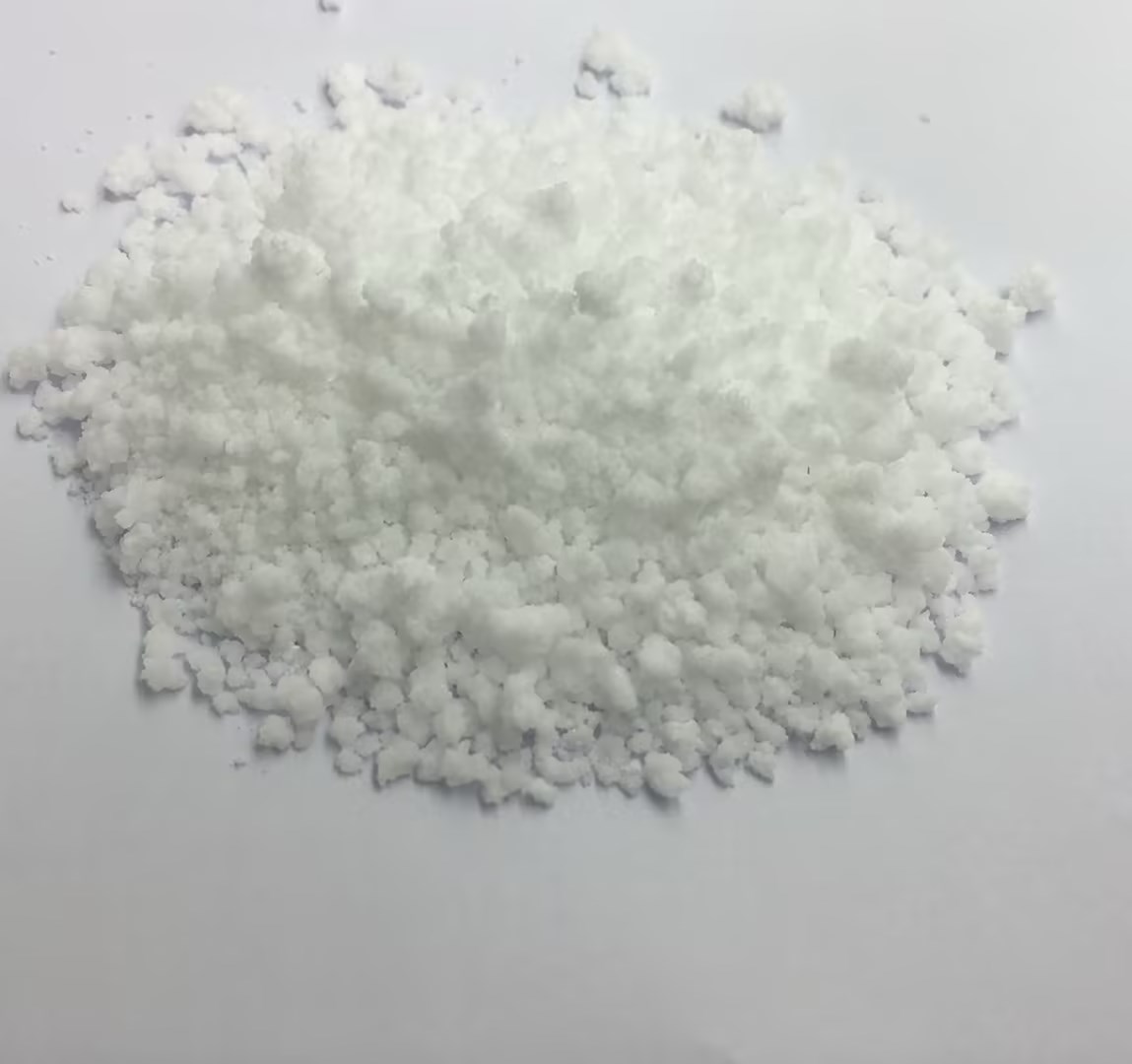

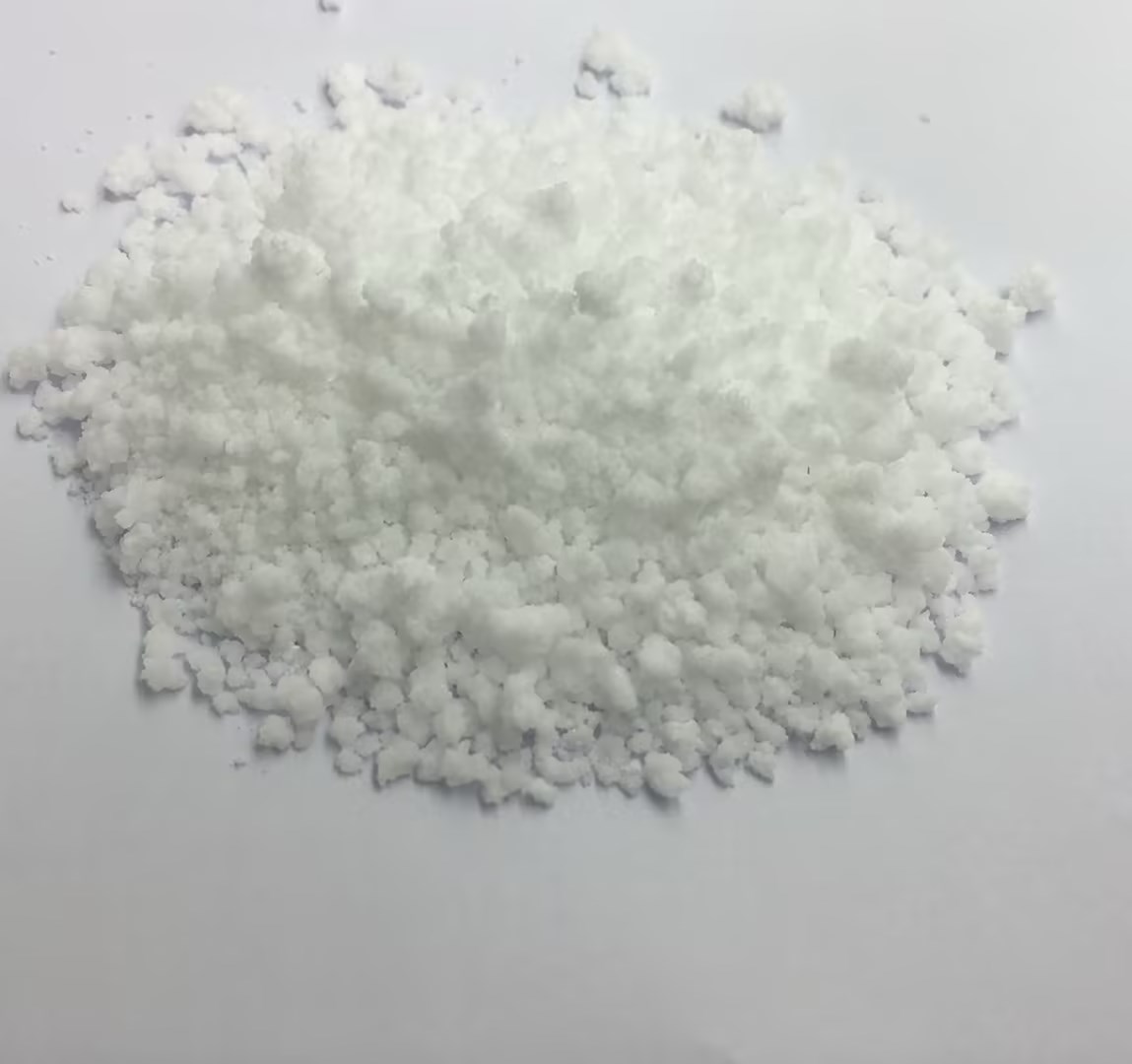

Gas phase white carbon black, molecular formula SiO2, commonly known as "nano white carbon black", is a white fluffy powder, porous, non-toxic, odorless, pollution-free, and heat-resistant. Its native particle size ranges from 7 to 80 nanometers, and its specific surface area is usually greater than 100 square meters per gram, which gives it significant nanoscale effects. Due to its small particle size and large specific surface area, gas-phase white carbon black exhibits extremely strong surface adsorption and surface energy, as well as high chemical purity, good dispersibility, and specific properties in terms of thermal resistance and electrical resistance. These characteristics endow gas-phase white carbon black with superior stability, reinforcement, thickening, and thixotropy.

2、 Production process

The main production process of gas-phase white carbon black is chemical vapor deposition (CVD), also known as pyrolysis or dry method. This process is made by reacting silicon tetrachloride, oxygen (or air), and hydrogen as raw materials at high temperatures. The specific process includes: sending the silicon tetrachloride raw material to the distillation tower for distillation, heating and evaporating it in the evaporator, and using dried and filtered air as a carrier, sending it to the synthesis hydrolysis furnace. At high temperatures, silicon tetrachloride undergoes gas-phase hydrolysis with a certain amount of hydrogen and oxygen after gasification, producing gas-phase silica particles. These particles are extremely fine and form aerosols with the gas, making them difficult to capture. Therefore, they need to be first aggregated into larger particles in an aggregator, collected by a cyclone separator, and then sent to a deacidification furnace for deacidification treatment, ultimately obtaining the finished gas-phase white carbon black.

3、 Application Fields

The application fields of gas-phase white carbon black are extensive, covering almost all industries that require high-performance materials. In the rubber industry, it can significantly improve the tensile strength, tear resistance, and wear resistance of rubber products as a reinforcing agent. In the plastic industry, it can be used as a filling agent to improve the strength and toughness of plastics. In the coatings and ink industry, it can improve the rheological properties and glossiness of coatings as a thickener and matting agent. In addition, gas-phase white carbon black is widely used in various fields such as petrochemicals, decolorizing agents, extinction agents, metal soft polishing agents, insulation fillers, advanced daily cosmetics fillers and spray materials, pharmaceuticals, and environmental protection.

It is worth mentioning that the application of gas-phase white carbon black in electronic packaging materials is also receiving increasing attention. Fully dispersing the surface active treated gas-phase white carbon black in the organic silicon modified epoxy resin encapsulation adhesive matrix can significantly shorten the curing time of the encapsulation material, and the curing temperature can be lowered to room temperature, thereby improving the sealing performance and service life of the OELD device.

4、 Market outlook

With the continuous development of nanotechnology and the continuous expansion of application fields, the demand for gas-phase white carbon black is expected to show a sustained growth trend. On a global scale, many well-known companies such as Evonik Industries, Wacker Chemie, and DeShan are actively seizing this market trend, using modern manufacturing technology to increase production capacity, reduce costs, and improve energy efficiency. According to a report from a market research company, the global market for gas-phase white carbon black is expected to continue expanding at a stable compound annual growth rate in the coming years.

Looking ahead to the future, gas-phase white carbon black will leverage its unique advantages in more fields, providing new material foundations and technological guarantees for the development of related industrial sectors. Meanwhile, with the continuous advancement of preparation technology and further cost reduction, the application scope of gas-phase white carbon black will also become more extensive, bringing more benefits to human society.

In summary, as a high-tech ultrafine inorganic new material, gas-phase white carbon black plays an irreplaceable role in materials science and industry due to its unique properties and wide application fields. We have reason to believe that in future development, gas-phase white carbon black will continue to shine with its unique brilliance.