Application of White Carbon Black in Textile Industry

White carbon black, as a high-performance silica material, has been widely used in various fields due to its unique physical and chemical properties. Especially in the field of textiles, the application of white carbon black not only enhances the performance of textiles, but also endows them with more functionality. This article will start from the basic properties of white carbon black and explore in detail its application in the textile field and the changes it brings.

1、 Basic properties of white carbon black

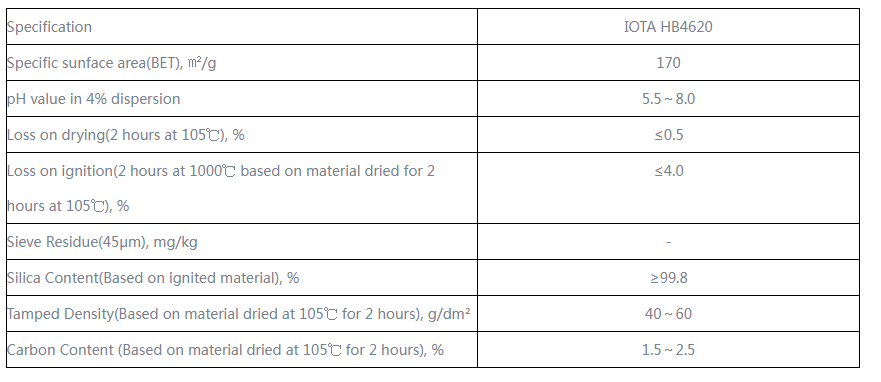

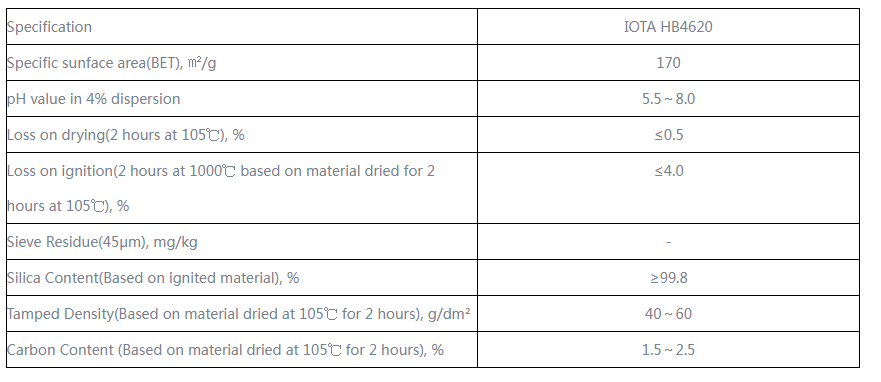

The main component of white carbon black is silicon dioxide, but unlike ordinary silicon dioxide, white carbon black is a type of silicon dioxide that has been physically and chemically modified to increase its activity. This modification gives white carbon black a higher specific surface area, stronger adsorption capacity, and better dispersibility. There are two main methods for preparing white carbon black: gas-phase method and precipitation method. The white carbon black prepared by gas-phase method has high purity and good dispersibility, but the cost is relatively high; Although the purity of white carbon black prepared by precipitation method is slightly lower, the cost is lower and it is more suitable for large-scale industrial production.

The micro nano scale pore structure of white carbon black endows it with excellent adsorption performance, capable of adsorbing and releasing moisture, as well as adsorbing fine particles and harmful gases such as sulfur dioxide and formaldehyde. In addition, white carbon black also has good wear resistance, weather resistance, and electrical conductivity, which make it have broad application prospects in the textile field.